Categories

EFFITEST P100 Series

The Effitest P100 Series delivers the power of the larger P900 platform in a compact, desktop form—perfectly suited for both laboratory and production environments. While it offers lower maximum power and pincount than the P900, it preserves the strengths of the Effitest architecture, including high-voltage and high-current instrumentation up to 2500 V / 300 A and advanced curve-tracing capability. This makes the Effitest P100 Series an excellent choice for efficient testing of diodes, BJTs, IGBTs, MOSFETs, JFETs, thyristors (SCRs), optocouplers, and more—all while minimizing required floor space.

Download brochure here

Download detailed presentation here

Extensions available:

- UIS/UIL Avalanche testing for EAS and EAR measurements

- Capacitance measurement - Rg, Cg, Ciss, Coss, Crss

Available Configurations p100 series

- Effitest p100 2500V / 10A

- Effitest p111 800V / 100A

- Effitest p112 800V / 300A

- Effitest p113 2500V / 100A

- Effitest p114 2500V / 300A

Modified version allows:

- Reverse Surge testing of Zener diodes

- Thermal resistance (Rth or dVSD) testing

Multi-site testing capability

- On a manual adapter(s)

- On wafer

- On a handler

- Ping-pong mode available (2 sites with 2 different devices)

TESTING (Wafer, Bare Die, Packaged Componets):

- Transistors (GaN, SiC, etc.)

- MOS-FETs

- IGBTs

- MES-FETs

- Diodes

- Rectifiers

- Bridges

- SCRs

- Thyristors

- Optocouplers

- Hybrid modules

- Power Devices

- Power Transistors

- Power Modules

Tested parameters

- Complete overview in the brochure here

Features

- Easy and fast menu-like TP programming

- High speed test - around 100 ms to test for high power MOS-FET, 50ms for a power diode

- Lowest current resolution - 300fA

- Autorange

- Throughput up to 72,000 UPH

- Single, Dual or Quad Configuration

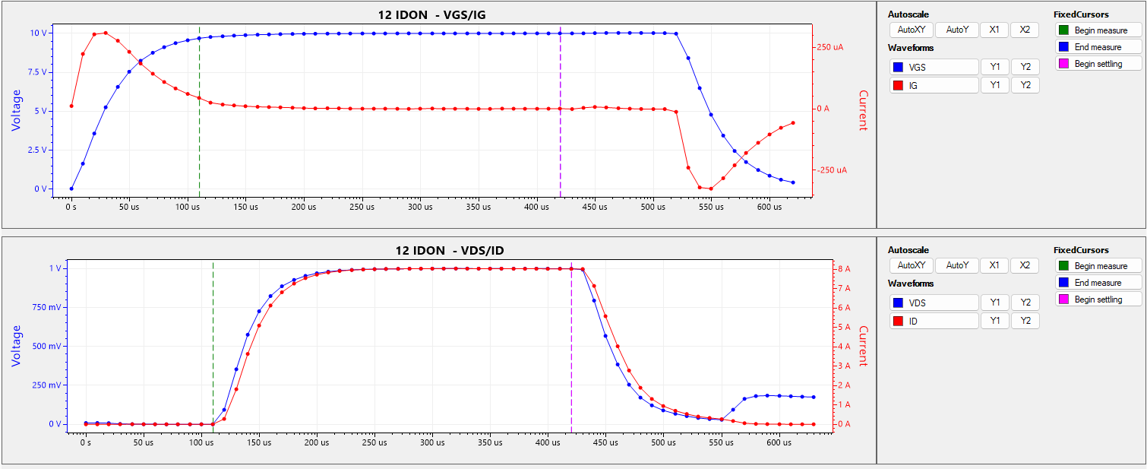

- Virtual scope – internal instrument allowing display of measured parameters – voltages, currents, etc. with 100kHz sample rate

- Automatic calibration / selftest

- Configurable test head - scalable platform

- Wide library of standard test methods (following MIL-STD-750, JEDEC and IEC 60747)

- Wafer mapping

- High-precision measurements – the tester delivers highly accurate results that meet strict industry standards.

- Modular and flexible design – easily adaptable to various testing scenarios and requirements.

- Ideal for both production and development – a perfect tool for fine-tuning and verifying new components and prototypes.

- Excellent price-performance ratio – cost-effective while maintaining high quality and reliability.

- Supports a wide range of components – compatible with various semiconductor and electronic components.

- Fast return on investment – efficient use of the tester leads to cost savings and increased productivity.

- Advanced automation capabilities – seamless integration into existing production processes.

- Intuitive user interface – simple operation for maximum work efficiency.

Technical specification

- CVI unit 2×VI source 30V/10A, HV source 800V/100mA and Leakage current meter from 10nA range

- High Current Source LVI 300A

- High Voltage Source HVI -2500V to +2500V

- Hi-current matrix MX1 with on board self-test

- Digitizer & Time Measurement Unit with 100kHz for DC measurements, 500MHz for AC measurements

- Resolution 16 bit force / measure

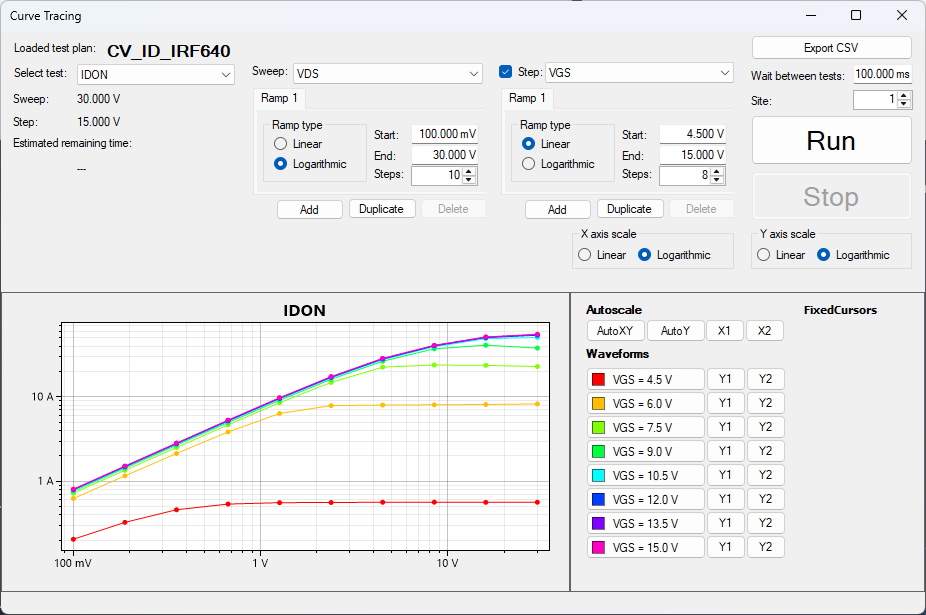

Curve tracing tool

- Linear & logarithmic measurements

- All DC parameters can be tested up to capability of the tester model (eg. P114 2500V/300A)

- Pulse widths down to 10 µs and up to tens of ms

- Sweeps & steps (single or multiple parameters)

- Detailed analysis for each step (Virtual Scope)

- Available also for capacities – Ciss, Coss, Crss, Rg, Cg

- Available both on wafer or packaged level

- Exports to CSV

Embedded digitizer (Virtual scope)

Areas of application

- High volume production testing

- Device characterization

- Quality control

- Failure analysis

- Engineering testing

Japan web page

Japan web page