Categories

KINALI Test-it-off

1. Gripping

Use Test-it-off to verify the output quality of products from any place. It can even handle unsorted material placed in a crate or KLT box. It can do this thanks to the integrated ‘bin picking’ system.

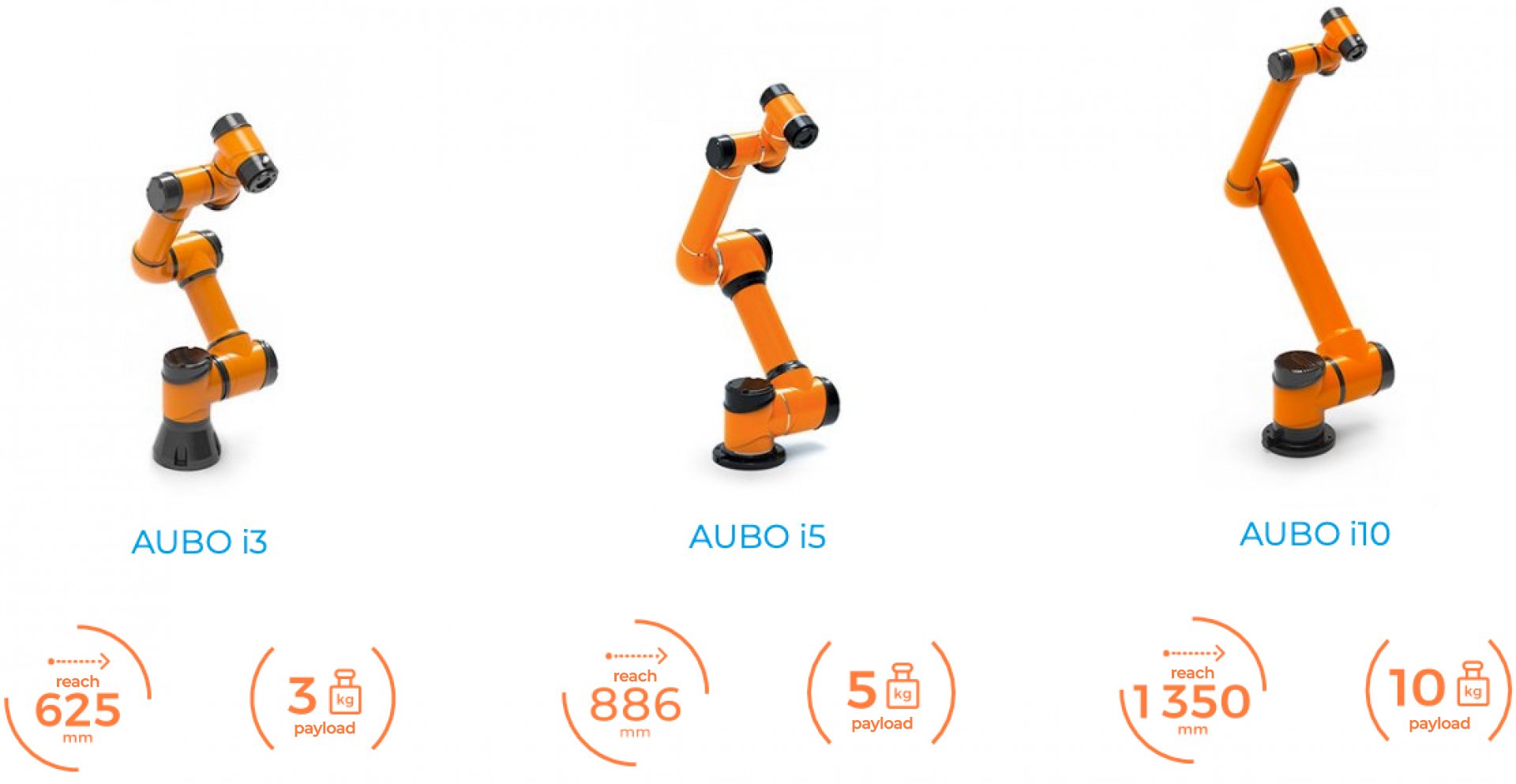

AUBO cobot – an integral part of Test-it-off

At the core of product handling in the Test-it-off system are AUBO collaborative robots.

They offer versatile automation options for production processes at an attractive cost. AUBO cobots are proven, reliable partners, backed by an 18-month warranty and round-the-clock support. Designed with simplicity and seamless integration in mind, they fit even the most demanding production environments. Already assisting in hundreds of operations worldwide, these orange partners can also support you in automating quality control.

2. Testing

Tailor-made testing equipment

The Test-it-off robotic arm can place products into virtually any testing device, making it ideal for operations where quality control relies on custom inspection setups. These may include ICT testers, precision scales, mechanical wear testers, chemical composition analyzers, or other instruments for evaluating physical and chemical properties.

A particularly powerful solution is the integration with advanced testers developed by UNITES Systems a.s., ensuring maximum compatibility and reliability.

As its name suggests, Test-it-off is primarily designed for off-line testing. With the right test equipment, it makes it possible to inspect up to 100% of production output—without slowing down the production line.

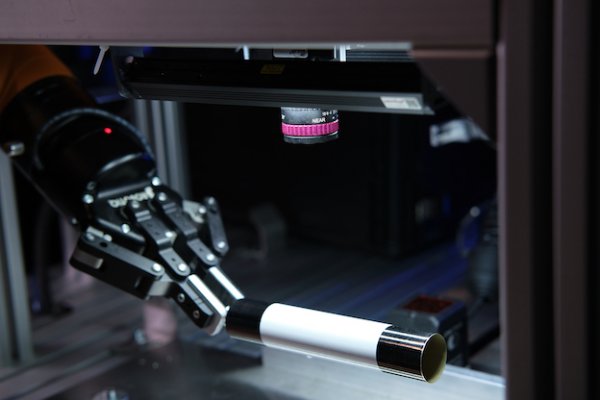

Camera system

A set of high-performance industrial cameras ensures precise optical quality control. The system can verify dimensions, colors, and surface quality, detecting even the smallest deviations invisible to the human eye. All measurements are carried out within milliseconds and with micrometre-level accuracy.

3. Sorting

After performing the quality check, Test-it-off takes care of sorting based on the specified parameters. The robotic arm removes the product from the testing section and moves it to the desired location.

Test-it-off can easily:

- Separate defective products from flawless ones

- Sort material by shape, colour, labels, surface quality or other input parameters

- Use artificial intelligence techniques

- Communicate with other production nodes to obtain up-to-date quality criteria

- Flexibly respond to changes and sort according to newly set criteria

It can handle different ways of sorting and storing products

Pallets

Printed circuit boards or other products susceptible to damage are often stacked on pallets. The attachment with vacuum suction cups or a soft two-finger gripper can be selected for handling. The selection depends on the type, fragility, dimensions and weight of the products. It also depends on the angle of their storage and the gaps between the individual pieces.

Custom containers, shelves and stands

Do you have products stored in containers or in shelves? No problem for the AUBO cobot! It grips the board and slides it out of the container with a suitable attachment. If the products are large-sized, a camera can be placed on the robot’s head and the inspection can be carried out directly from the rack and stands. All this without the need for manipulation.

Conveyors

The AUBO cobots excel in their variability. Thanks to this, the cycle of the entire Test-it-off solution can be aligned with the speed settings and possibilities of belt conveyors. These are also often used to build up a sufficient stock of products when long term autonomous work is required. It follows that Test-it-off is also suitable for checking products that do not have a static location.

KLT or other boxes

The easiest and least demanding product storing option for each production company is unsorted storage in KLT boxes or other crates. Test-it-off can handle even this situation. It can find, test and sort each product thanks to the integrated bin-picking system with a 3D camera.

4. Reporting

Smart quality control and full traceability

With automated quality control, you gain clear insight into the state of production. The user interface provides notifications on inspection progress, defect counts, or the utilisation rate of Test-it-off over a selected period. You can also define and monitor your own custom metrics.

Test-it-off delivers a complete overview of operations, including full traceability of results. It is designed in line with Industry 4.0 principles:

- Seamless data connection to ERP or MES systems

- Real-time response to inputs from other production nodes

- Transmission of detailed information about test cycles

- Automated data backup for reliability

Planning to let Test-it-off run overnight on its own? No problem. It won’t be “afraid in the dark” — and if it needs your attention, it will notify you via the user interface, email, or SMS.